The most critical factor in surviving a house fire isn’t just the alarm; it’s the time you have to escape.

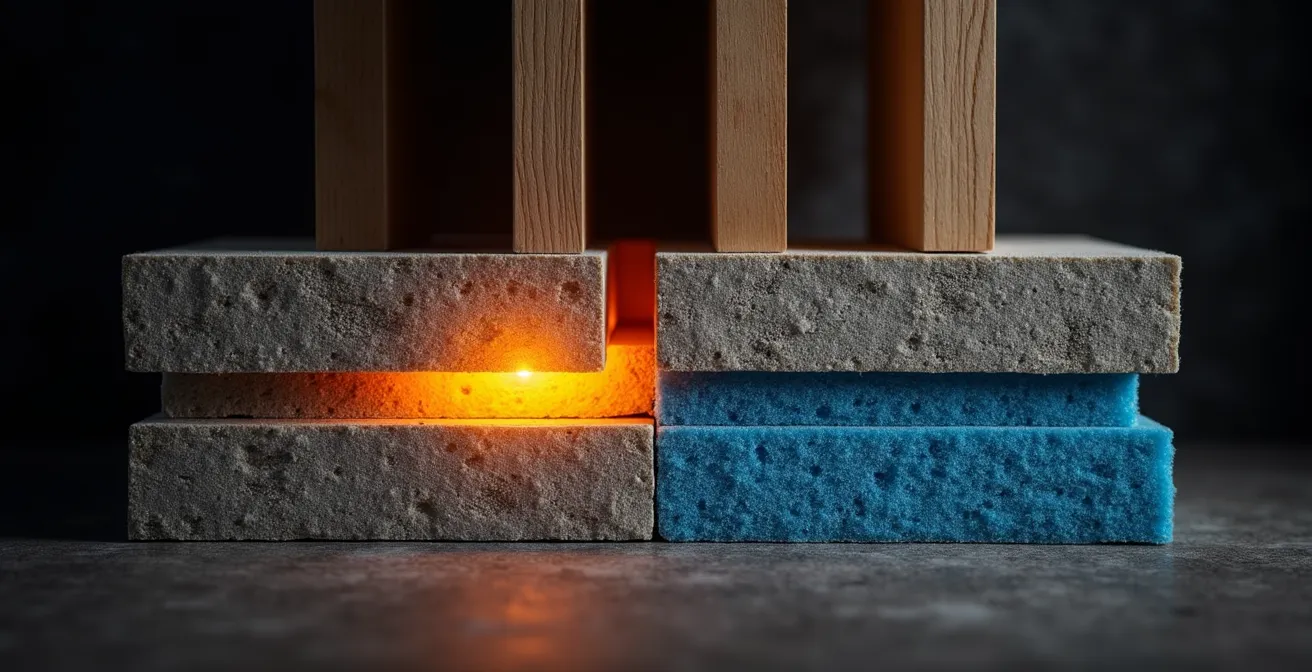

- Stone wool insulation acts as a passive fire barrier, containing flames within a room and not producing significant toxic smoke.

- It maintains structural integrity by protecting wood framing far longer than combustible alternatives like polystyrene or uncertified spray foam.

Recommendation: Verifying that you have ULC-certified, non-combustible insulation in your home’s critical areas is one of the most important upgrades you can make to your family’s fire safety plan.

The sound of a smoke alarm at 2 a.m. is a moment of pure terror. In that instant, every choice you’ve made about your home’s construction suddenly matters. You have minutes, maybe only seconds, to get your family out. Most people think about fire safety in terms of active systems: alarms and extinguishers. These are vital, but they are reactive. They tell you a fire has started; they do little to slow it down.

The conversation we rarely have is about passive fire protection—the silent, built-in systems that actively work to contain a fire and protect escape routes. This isn’t about fancy technology. It’s about the fundamental materials inside your walls. The standard approach is to focus on insulation’s thermal properties, its R-value. But from a fire safety expert’s perspective, that’s only half the story. The other, more critical half is its behaviour in a fire.

What if the walls of your home could buy you precious, life-saving time? This article moves beyond R-value to explain the physics of fire spread in a typical wood-frame house. We will deconstruct how the choice of insulation is not just a matter of energy efficiency, but a critical component of a survival strategy. It’s the difference between an inferno and a contained incident, and it could give you the 15 extra minutes you need.

This guide will walk you through the key areas of risk and protection, from the unique dangers of century homes to the fine print in your insurance policy. Understanding these concepts is fundamental to ensuring your home is a true sanctuary for your family.

Summary: How Insulation Choices Impact Fire Survival Time

- Why Non-Combustible Insulation Matters for Chimney Chases?

- How to Create Fire Blocks in Balloon-Framed Century Homes?

- Will Installing Fire-Resistant Insulation Lower Your Home Insurance Quote?

- Polystyrene vs. Rock Fiber: Which Melts First at 1000°C?

- Where to Prioritize Fire-Resistant Batts for Safe Bedroom Egress?

- Why Smoke Development Ratings Matter More Than Flame Spread in High-Rises?

- The Hidden Health Risks of Grey Market Insulation Materials

- Why Your Insurance May Deny a Claim Involving Non-ULC Spray Foam?

Why Non-Combustible Insulation Matters for Chimney Chases?

A chimney chase—the hidden cavity surrounding a metal flue pipe as it passes through floors and attics—is one of the most vulnerable areas in a home. It’s a direct, vertical pathway for extreme heat. If a fire starts in or near this chase, or if the chimney itself overheats, any combustible material inside that cavity will ignite. This is a common and devastating source of house fires that are incredibly difficult to fight once they take hold inside the walls.

This is where the material choice is not just important; it is everything. Many common insulation materials are combustible. Stone wool, however, is fundamentally different. It’s made from rock. Because of this, studies show that ROCKWOOL stone wool can resist temperatures up to 2,150°F (1,177°C) without melting, smoking, or burning. It provides passive fire containment, holding back the flames and heat from spreading to the wooden structure of your home.

For a high-risk zone like a chimney chase, using a non-combustible material is a non-negotiable safety measure. It ensures that the cavity itself cannot become fuel for the fire, effectively containing the threat. This is not just a recommendation; it’s a core principle of fire-safe building, reflected in Canadian building codes.

Your Checklist for Chimney Installation Safety

- Verify Material Choice: Ensure stone wool insulation is specified, allowing for zero clearance installation directly against chimney flues where permitted by the chimney manufacturer.

- Confirm Code Compliance: Check that the installation meets or exceeds the National Building Code of Canada Section 9.10 requirements for fire protection and material ratings.

- Inspect the Installation: Use a friction-fit method to ensure the entire cavity is completely and seamlessly filled, leaving no gaps for heat or flames to bypass.

- Check for Certification: Look for the ULC (Underwriters Laboratories of Canada) certification mark on all insulation product packaging to guarantee it has been tested for the Canadian market.

- Ensure Continuity: For older homes, confirm that continuous fire blocks have been installed at each floor level within the chase to prevent vertical fire spread.

Choosing the right material here doesn’t just insulate a pipe; it builds a firewall at the very heart of your house.

How to Create Fire Blocks in Balloon-Framed Century Homes?

Many older Canadian homes, particularly those built before the 1950s, use a construction method called “balloon framing.” Unlike modern platform framing where each floor is a separate structure, balloon-framed walls have studs that run continuously from the foundation to the roof. This creates open, uninterrupted cavities inside the walls that span multiple stories. From a fire’s perspective, these cavities are superhighways, allowing flames, smoke, and superheated gases to race from the basement to the attic in minutes, completely bypassing any smoke alarms on the main floors.

The solution to this critical vulnerability is fire blocking. This involves inserting a non-combustible material horizontally within the vertical wall cavities at each floor level to break the path of the fire. Stone wool insulation is the ideal material for this task. It’s dense, easy to cut and friction-fit securely into the stud bays, and, most importantly, it will not burn or shrink away from the studs when exposed to intense heat, maintaining the integrity of the block.

As the diagram shows, the stone wool batt acts as a barrier, effectively compartmentalizing the wall. This simple retrofit contains a fire to its floor of origin for a longer period, slowing its vertical spread and providing your family with critical extra time to escape. This isn’t a theoretical exercise; it’s a proven method.

Case Study: Tested Fire Resistance

In a demonstration of this principle, a floor assembly protected with stone wool fire blocking was subjected to a standardized fire test (ASTM E119). The system was approved as a fire-resistant assembly under the International Residential Code, proving its effectiveness in maintaining structural separation and preventing fire from passing from one floor to the next. This test confirms that proper fire blocking transforms a dangerous, interconnected cavity into a series of contained, more manageable spaces.

For owners of century homes, investigating your wall structure and retrofitting fire blocks is one of the most impactful safety upgrades you can make.

Will Installing Fire-Resistant Insulation Lower Your Home Insurance Quote?

While there’s no universal discount automatically applied by every insurance company, the choice of insulation absolutely impacts your home’s risk profile, which is the foundation of any insurance policy. Insurers are in the business of managing risk. A home built with non-combustible materials that actively resist the spread of fire presents a lower risk of a total-loss claim than one filled with combustible plastics.

Think of it from the underwriter’s perspective. Materials like spray foam or polystyrene are, at their core, solid fuels. When they ignite, they not only contribute to the fire’s intensity but also release dense, toxic smoke. This significantly increases the potential for property damage and raises the risk of a claim being denied if the product was not installed with the correct thermal barriers or, worse, was not ULC-certified for use in Canada.

Installing stone wool insulation is a statement to your insurer that you have proactively mitigated risk. It demonstrates a commitment to building beyond the bare minimum of the code. While it may not always result in an immediate premium reduction, it can be a critical factor in securing coverage, especially for custom or high-value homes. More importantly, it drastically reduces the likelihood of an insurer denying a claim due to the failure of a combustible product that was improperly installed or uncertified.

The following table, based on material properties and their standing in building codes, illustrates how an insurer might view the risk associated with different insulation types.

| Insulation Type | Fire Rating | Code Compliance | Insurance Impact |

|---|---|---|---|

| Stone Wool | Non-combustible (2,150°F) | Exceeds all codes | Reduces claim denial risk |

| Fiberglass | Non-combustible (1,500°F) | Meets basic codes | Standard coverage |

| Spray Foam | Combustible (700°F) | Requires thermal barrier | Potential coverage issues if non-certified |

The peace of mind comes not just from the fire protection itself, but from knowing you have built a defensible home in the eyes of those who will be there to help you rebuild.

Polystyrene vs. Rock Fiber: Which Melts First at 1000°C?

This question is not just academic; it gets to the heart of what happens in the first few minutes of a fire. The answer is stark: at 1000°C (1832°F), rock fiber (stone wool) is essentially unchanged. Polystyrene, on the other hand, is not just melted—it has been consumed by fire long before reaching that temperature, adding fuel and toxic smoke to the blaze.

The “chain of failure” in a fire is critical to understand. Polystyrene insulation, a plastic, has an extremely low ignition temperature. According to fire engineering resources, polystyrene ignites at approximately 350-400°C (662-752°F). In a typical house fire, temperatures can exceed 1100°F (600°C) within five minutes. This means that polystyrene insulation will not just melt; it will actively burn, releasing a thick, black, toxic smoke and dripping molten plastic that can spread the fire to other surfaces.

Rock fiber, being made of stone, is non-combustible. It does not contribute any fuel to the fire. As it withstands temperatures far beyond the peak of a typical house fire, it stays in place, protecting the wooden studs and structural elements behind it. This maintains the integrity of the wall or floor assembly, preventing collapse and keeping the fire contained.

The visual difference is absolute. Where one material becomes a source of fire and toxic smoke, the other remains a steadfast barrier. This performance difference is what buys you time. While plastic foams are failing and accelerating the fire, stone wool is holding the line, maintaining the structural integrity of your escape route.

You are not just choosing an insulator; you are choosing whether to line your walls with a fire barrier or with solid fuel.

Where to Prioritize Fire-Resistant Batts for Safe Bedroom Egress?

In a fire, your family’s survival depends on having a clear and protected path from their bedrooms to the outside. This path is your egress route. The strategy is to create “defensive zones” by using fire-resistant insulation to fortify the walls and ceilings along these critical pathways. If a fire starts, these reinforced zones will slow its spread, keeping hallways and stairwells passable for a longer duration.

You don’t necessarily need to insulate every interior wall in your home. The key is to be strategic. By focusing on the assemblies that separate sleeping areas from the rest of the house and from high-risk zones, you create a sanctuary that buys you the most precious commodity in a fire: time. The goal is compartmentation—keeping the fire contained in its room of origin and away from your escape path.

For any safety-conscious parent, especially those in wood-frame homes, prioritizing the installation of non-combustible stone wool batts in the following areas is a critical life-safety upgrade. This is not about comfort; it is about building a shield around your family.

- Utility and Furnace Rooms: Install fire-resistant batts in the walls and ceiling of any room containing a furnace, water heater, or electrical panel. These are high-risk ignition sources.

- Attached Garage Wall: The wall separating an attached garage from your living space is a critical firewall. Garages often store flammable liquids and vehicles, posing a significant threat.

- Hallway Walls: Line all hallway walls that lead from the bedrooms to an exterior door. This turns your main escape route into a protected corridor.

- Floor/Ceiling Assembly: In a two-story home, adding fire-resistant insulation to the floor/ceiling assembly between the main floor and the upper bedrooms is crucial. It slows a fire from burning up through the floor into sleeping areas.

- Around Sleeping Areas: Insulate the walls around all bedrooms to create a final defensive perimeter, giving occupants more time to wake up and react before smoke and fire breach the room.

By fortifying these key areas, you are building a passive defense system that stands guard 24/7, protecting your family while they are most vulnerable.

Why Smoke Development Ratings Matter More Than Flame Spread in High-Rises?

In the world of fire testing, materials are given two primary ratings: Flame Spread and Smoke Development. Flame Spread measures how quickly a fire moves across a material’s surface. Smoke Development measures the density of smoke it produces when it burns. In a single-family home with multiple ground-floor exits, both are important. But in a high-rise building, the dynamic changes completely. The real killer is smoke.

Escape from a high-rise apartment is often vertical and slow, involving long corridors and crowded stairwells. In this scenario, a fire that produces little flame but enormous volumes of thick, toxic smoke can be far deadlier than a clean-burning fire. Smoke obscures exits, causes disorientation, and leads to asphyxiation long before the flames arrive. This is why, for multi-story residential buildings, the Smoke Development rating of an insulation material can be even more critical than its flame spread.

Combustible plastic foam insulations are notorious for producing dense, dark, and highly toxic smoke when they burn. Even if treated with flame retardants to slow the flame spread, they can still release a deadly amount of smoke. As the ROCKWOOL Group’s research highlights, this is the primary danger occupants face:

Toxic smoke inhalation causes more fire-related deaths than do the fires themselves.

– ROCKWOOL Group, Fire Resistance Research

Non-combustible stone wool insulation, because it is made from rock, does not burn. Consequently, it has a Smoke Development rating of virtually zero. It contributes no significant smoke to a fire, helping to keep escape routes clearer and more tenable for a longer period. For families living stories above the ground, this characteristic is not a luxury; it’s a lifeline.

In a high-rise fire, you are far more likely to be defeated by what you can’t see than by what you can. Choosing materials that don’t add to the smoke is paramount.

The Hidden Health Risks of Grey Market Insulation Materials

In any home renovation project, the temptation to save money with off-brand or “grey market” materials can be strong. However, with a product as integral as insulation, this is a dangerous gamble. Uncertified insulation products, often sold through unofficial online channels without proper documentation, pose significant risks that go far beyond poor thermal performance. They present direct threats to both your family’s health and their safety in a fire.

In Canada, the ULC (Underwriters Laboratories of Canada) mark is the gold standard. It certifies that a product has been rigorously tested and meets the stringent safety requirements of the National Building Code of Canada. A product with only a “UL” mark (from the United States) may not be sufficient. Uncertified products have no such guarantee. They may have fraudulent fire ratings, meaning they will burn when they are claimed to be non-combustible.

Beyond the immediate fire hazard, these materials can introduce long-term health risks. They may be manufactured with harmful chemical binders that release high levels of VOCs (Volatile Organic Compounds) into your home’s air for years. In some cases, they have been found to contain substances that are banned in Canada due to their toxicity. You are not just putting an unknown product in your walls; you are potentially embedding a source of chronic indoor air pollution.

The money saved on an uncertified product is a trivial sum compared to the potential cost to your family’s well-being and the risk of catastrophic failure in a fire.

Key Takeaways

- Insulation’s primary role in fire safety is to act as a passive barrier, buying critical time for escape by containing fire and protecting the home’s structure.

- Non-combustible materials like stone wool withstand extreme heat without burning or producing toxic smoke, unlike plastic foams which act as fuel.

- In Canada, always verify the ULC mark on insulation to ensure it meets national safety standards and to avoid potential insurance claim denial.

Why Your Insurance May Deny a Claim Involving Non-ULC Spray Foam?

After a devastating house fire, the last thing any family wants to face is a battle with their insurance company. Yet, this is a real possibility if the fire is found to have involved non-compliant building materials. Insurance policies are contracts based on a certain level of assumed risk. The use of uncertified products, particularly combustible ones like spray foam that lack the mandatory ULC mark in Canada, can be seen as a breach of that assumed risk.

Spray polyurethane foam (SPF) is combustible. Even when treated with fire retardants, it remains a recognized fire hazard. The U.S. Consumer Product Safety Commission (CPSC) has noted that spray foam will combust when it reaches 700°F (371°C), a temperature quickly reached in any house fire. If this material is installed without the proper thermal barrier (like a 1/2-inch layer of drywall) or if the product itself isn’t ULC-certified for that specific application, an insurer could argue that the homeowner created an undue hazard.

The financial stakes are astronomical. In the United States alone, a study found that in 2018, fires caused property damage exceeding $25.6 billion. Faced with such massive potential payouts, insurance companies meticulously investigate the cause and spread of a fire. If an uncertified plastic foam is found to have contributed to the rapid spread of the fire or the production of damaging smoke, it can provide grounds for reducing the payout or denying the claim altogether.

Your next step should be a critical review of your home’s defenses. Conduct a fire safety audit of your insulation, verify its certification, and ensure your home’s first line of defense is one you can trust completely. This proactive assessment is the most important step you can take to protect both your family’s lives and your financial future.

Frequently Asked Questions on Fire-Resistant Insulation

What is the difference between UL and ULC certification?

ULC (Underwriters Laboratories of Canada) certification is mandatory for Canadian building code compliance, while UL alone may not be sufficient. ULC testing protocols are specifically designed to meet the requirements of the National Building Code of Canada. Always verify ULC marks for Canadian installations to ensure full compliance and safety.

How can I verify genuine ULC certification?

Request the ULC certification number from suppliers and verify it on the official ULC online directory. Be wary of products sold through unofficial channels or at a steep discount without proper documentation. Authentic certification is your only guarantee of tested performance.

What risks do uncertified insulation products pose?

Beyond the catastrophic failure in a fire, uncertified products pose significant health risks. They may contain harmful chemical binders that release high levels of VOCs (Volatile Organic Compounds), degrading your home’s air quality. They could also include substances that are banned in Canada, posing long-term health risks to occupants.